Metal production

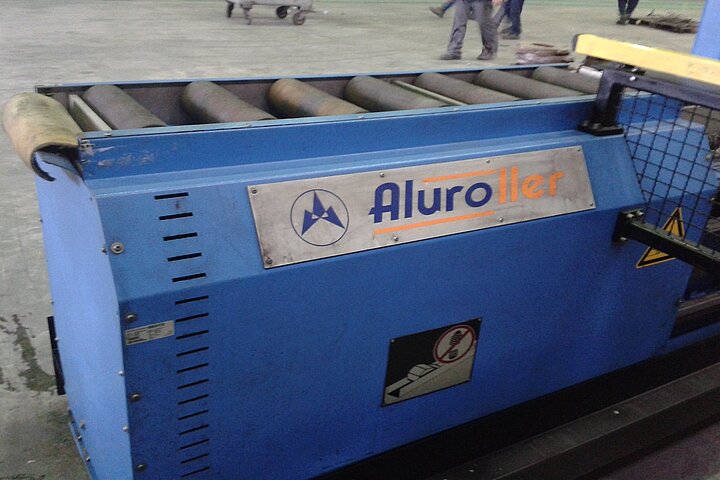

ALUROLLER THERMAL BREAK LINE - ALURO-LLER

Ref. No.:ALUROLLER140201

YEAR:2004

Brand:ALURO

Qty:1 Second-hand Thermal Break Assembly Line – ALURO-LLER

Specification

| Description | ALUROLLER THERMAL BREAK LINE - ALURO-LLER |

| Ref. No. | ALUROLLER140201 |

| Year | 2004 |

| Brand | ALURO |

| Qty. 1 Second-hand thermal break assembly line – ALURO-LLER | |

| Mfc. | BACCINI SRL Type |

| Motor power | 60 kW Control system |

| Strip width | 120 – 230 mm Thickness |

| For production of profiles in the range of | 37, 39 mm by 120 mm |

| 45 mm by 149 mm 54 mm by 158 mm 77 mm by 230 mm width | |

| Air valves | Metalwork Max. working width |

The assembly of the thermal break for aluminium profiles are using in production of | |

| windows, doors, curtain wall etc. | |

First step of the process is to place on the machine two aluminium profiles, then fill both | |

| profiles with polyamide and finally pressing together. | |

| It does simultaneously in one movement the knurling, pressing and assembly. | |

| Scope of supply | Uncoiler Tunnel furnace |

| set of different forming rollers with polyuretne injector Tunnel furnace | |

| automatic saw up to 12 m punching machine assembly machine | |

| automatic unload mechanism | |

| Benefits ALUROLLER | |

3-in-1 machine max. 2 operators freedom in strip-design lower cost per meter short set-up times reduced strafcel | |

| also complex profiles no damage 1st profile is good | |

| outfit for further automatization | |

| Quality | |

| Straight assembled profiles | |

| Respect of geometry | no deformation or deterioration during operation |

| Assembled profile into tolerance Excellent T&Q values | |

| Reliable and accurate equipment CE - Standards | |

| Human Resources | |

| Medium skilled operators required Maximum 2 operators | |

| User friendly | Windows operating system with language tool |

| Man-free automization possible | |

| Performance | |

| Proven cost-effectiveness for small (up to 50%!) and also big runs. | |

| “3-in-1” machine | reduced surface required |

| Very low fall-out and waste ratio | extrusion is clamped during process; this results in ± zero% loss of profiles; extremely important in case of small runs (like bicolors or dual-coloured profiles)! |

| Profitability | software allows production analysis |

| Factory floor efficiency | packaging of tooling allows efficient storage |

| Integrated performance solutions for evacuation of profiles | roller table/conveyor/return |

| with integrated packaging | |

| Other “customer-based” solutions of profile evacuation possible | |

| Freedom of design for profile and strip (strip is gripped and pulled in) | |

| System is ready for further man-free automization |